Hello, welcome to visit MaAnShan Davedew precision tool co.,ltd!

Mobile Terminal

Mobile Terminal

English

Chinese

Carbide blades, metal longitudinal scissors, zirconia ceramic blades and various shaped blades

TEL:

0555-6062199

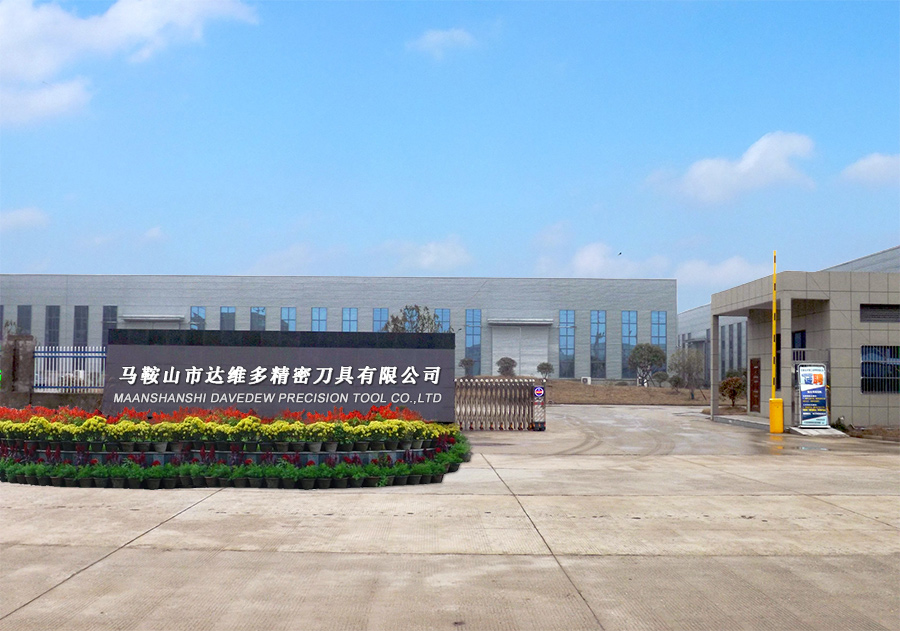

Maanshan Davedew precision cutting tool co., LTD. Is located in bowang district, maanshan city, with convenient transportation, 314 provincial highway connecting jiangsu, zhejiang, Shanghai and anhui through the industrial zone, and only 26 kilometers away from nanjing lukou international airport. Davido cutting tools is an enterprise with advanced management concept and production technology, the main products include: carbide blades, metal longitudinal scissors, zirconia ceramic blades and a variety of special-shaped blades. Products are widely used in paper, chemical fiber, glass fiber, film, leather, copper foil and aluminum foil. After the development in recent years, in personnel and equipment, has reached a certain strength. Davido cutting tools factory area of about 2500 square meters, with a number of modern workshops, the company has a variety of processing equipment including CNC machine tools, processing centers, all kinds of automatic, semi-automatic processing machine tools, testing equipment. Davedo tools can provide you with safe and reliable blade OEM service, according to customer needs or drawings, design and manufacture high-quality blades for customers.

Davedew has launched a series of carbide blades to replace imports in the domestic copper foil, aluminum foil and lithium battery industries. The developed copper foil slitting blades, aluminum foil slitting blades and thin film slitting blades have been well received by customers in the industry. With excellent equipment, exquisite technology, strict inspection and advanced management, our product quality has always been in the forefront of the industry, since its establishment, the company to produce high-quality products, create their own brand, adhering to the purpose of continuous improvement, enhance customer satisfaction. It has been based on honesty, seeking truth from facts, stepping step by step, forward to develop, with excellent product quality, perfect after-sales service, created the customer satisfaction of the corporate image, won the customer's appreciation and support, established a broad market space.

Davedew tools in the production process of strict control, outstanding performance in the following aspects:

1. The chemical composition of the product is optimized and scientifically controlled. In addition to conventional elements, an appropriate amount of precious and rare elements are added as the main metamorphic agent. In order to quickly and accurately test and adjust the chemical composition, the company invested a lot of money in the laboratory equipment to ensure the required target value of the product.

2, forging through forging can eliminate the metal in the smelting process produced in the cast state of porosity and other defects, optimize the microstructure, and because of the preservation of complete metal streamline, forging mechanical properties are generally better than the same material casting. In machinery, the important parts with high load and severe working conditions, in addition to the simple shape can be rolled plate, profile or welding parts, the use of forgings.

3, heat treatment heat treatment process is to ensure and improve the product quality of the very important process, good cutting quality, only through advanced heat treatment equipment and heat treatment process, can be fully reflected. The company has advanced heat treatment equipment, so as to ensure that the workpiece in a specific time and process in accordance with the required matrix standards for transformation, to achieve great unity. This is the crystallization of technology that we have been developing and striving to create.

4, machining with the continuous improvement of the requirements for the accuracy of sheet metal processing, we have developed ultra-high precision cutting tools, precision has only precision milling tools can match. ±0.001mm thickness tolerance, and ra0.1cm surface roughness, have been our standard. Using our technical know-how and expertise, we can also meet customers' higher tolerance requirements for thickness, parallelism, flatness, outer circle and inner circle. We can now ensure that the thickness tolerance is up to ±0.0005mm for certain inner circle, and the tolerance is up to H4. All high-precision product inspections are conducted in a thermostat.

5. The advanced processing and testing equipment strictly guarantees the qualified rate of the outbound products.

Address: western industrial concentration area, bowang district, ma 'anshan city

Telephone: 0555-6062199 fax: 0555-6062099

Consulting mobile phone: 18655503954

Mail box: zds@davedew.com

mobile terminal

WeChat public account